Processes

Slitting

Slitting is a process in which a coil is cut down to a narrower width and formed into smaller coils. This process is conducted by sending the coil lengthwise through the slitter's circular knives and reaching the required width of each new individual coil. The knives are job specific and vary based on the material gauge, the type of material, and the tolerances of the steel.

New Process Steel has facilities dedicated soley for your slitting needs and can slit to widths of less than 1"

Blanking

Blanking is one of the production processes offered by New Proces Steel in which the coil is leveled and slit in one step. Steel is cut to a specific width and length by means of running through a slitter head to obtain a narrower dimension and then cutting to the appropriate length.

Cut to Length & Leveling

Cutting to length and leveling is another standard capability that New Process utilizes. When leveling material, there is more than one way the material progresses. One function can be tension leveling, which results in the coil achieving maximum flatness - adding to the quality of the metal. A second function not only results in the flattening of the coil, but can also cut sheets to varying lengths.

Stamping

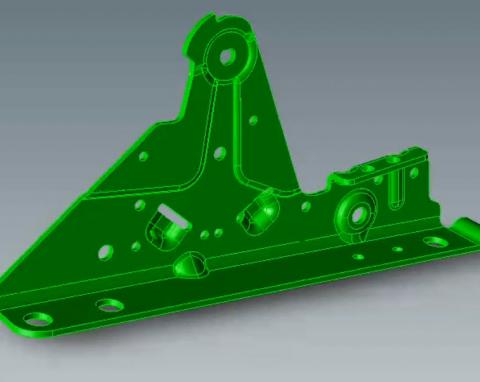

Stamping is the term used to indicate various press forming operations such as embossing, blanking, coining, and pressing. It is the process of forming metals using pressure into the surface of metal, normally a sheet or strip.

The most common operations associated with stamping are piercing, forming, blanking, and drawing. These operations are performed with dedicated tooling called hard tooling. Hard tooling is used to create high volume parts of one configuration of part design.

Our stamping and fabrication expertise can help optimize the OEM supply chain without fragmentation or loss of control.

Soft Tooling

Soft tooling is used to make processes such as CNC turret presses, laser profilers, and press brakes.

Soft tooling can be easily adjusted or modified.

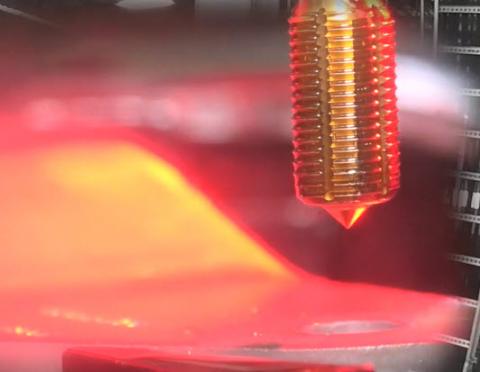

Welding

New Process Steel offers submerged and open arc welding services as well as MIG welding to complement our other steel processing capabilities. Since we have full-service welding capabilities, we are able to save our customers time and money in the production process.

Regardless of the type of welding your products need, New Process Steel provides high quality, efficient welding. We are here to alleviate stress not add to it.

Riveting

As a major component in the fabrication of sheet metal, New Process Steel is capable of riveting and conjoining any of your assembly needs.

PEM Insertion

At New Process Steel, we can insert PEM brand fasteners into your design projects. PEM Insertion produces strong, permanent, threaded fasteners and mounting points for PC boards, electronic enclosures, brackets, shield covers, and other accessories.

A PEM nut is an internal fastener that offers strong, load bearing threads to thin sheet metal as well as non-malleable materials. PEM insertion provides many benefits such as:

- Easy integration & Inexpensive

- Gives strength to your assembly

- Can clinch sheets as thin as .016 in./0.4 mm

- Can attach sheets as thin as .008 in./0.2 mm

To insert this exclusive software into your design projects, we will use surface mounting, weld technology, and presses.